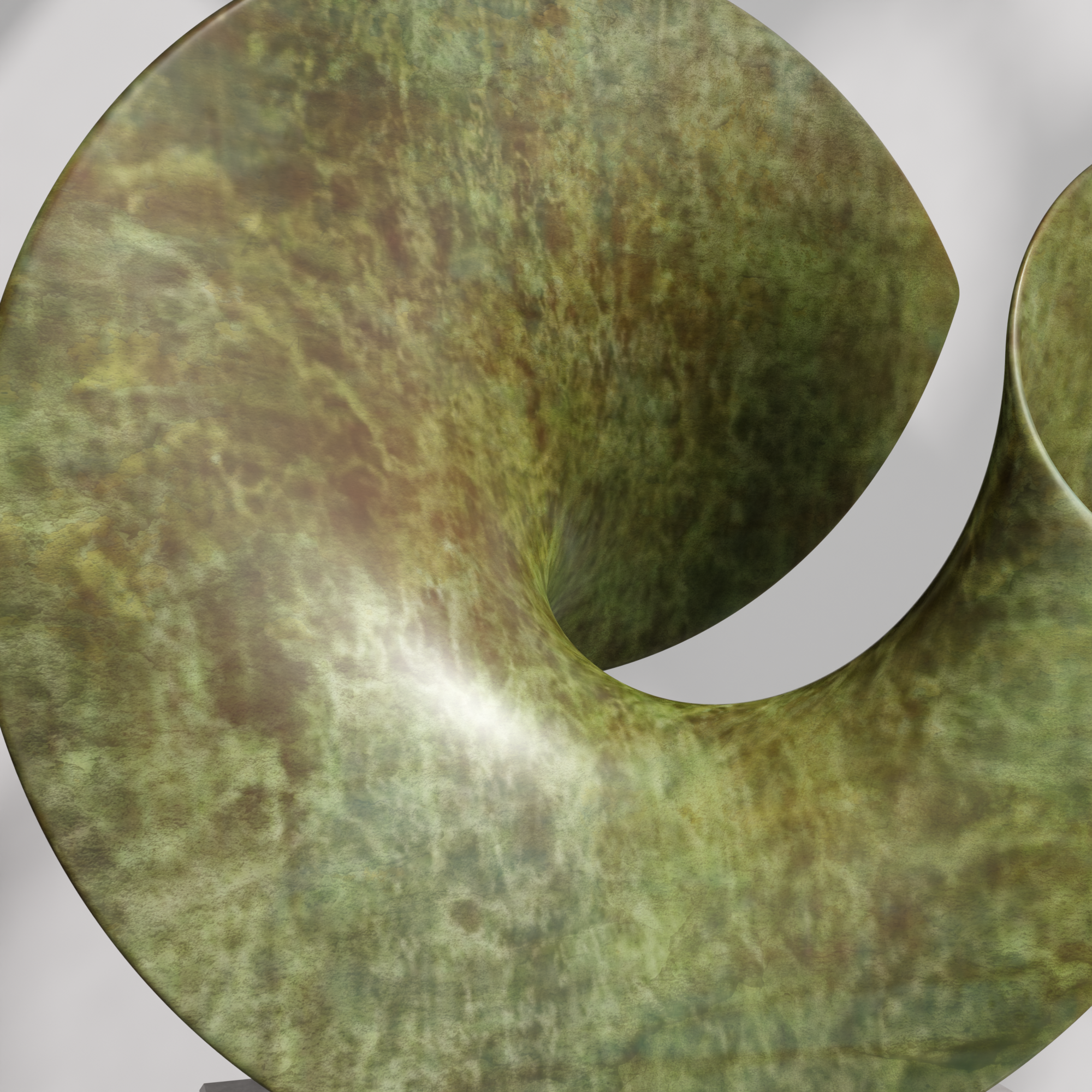

Iron and Copper Green Patina Recipe and Method

Iron and Copper Green Patina

Naturalistic patterned patina, with iron and green being the predominant colours. The contrasting colours create an intense, vibrant surface colour and when applied in thin layers a real translucent depth can be achieved. The application of this patina is straight forward, the patterning is dictated by the brush, the balance of colours and the quantities of chemicals in the solution.

Metal Preparation

Material : Cast Silicon bronze

Surface Prep : Sand to a smooth 80 or 120 grit finish to ensure optimal adhesion.

Base Coat Colour

Chemical Used : M20 Antiquing Solution / Liver of Sulphur / Ammonium Sulphide

Warm the bronze gently, taking care not to overheat.

Apply a weak solution of M20 evenly, allowing the surface to develop colour gradually.

Rinse thoroughly with water and brush to neutralise the reaction and remove residue.

Heat until a fine dusty film forms on the surface, then use a soft abrasive pad (e.g., 120 grit Scotch-Brite) to remove it.

Wash and repeat until you reach the desired finish.

First Coat

Water 250ml

2 teaspoons Medium Copper Nitrate

1/4 teaspoon Iron Nitrate

Heat the bronze evenly so the solution lightly sizzles and evaporates upon contact.

Carefully take small amounts of solution into the brush at each application, as the brush warms up it naturally sucks the solution into the brush.

Use a small brush to mix the solution, the two main components will settle out over time.

The oxide that forms on the surface of the bronze should develop into a green hoop or ring with a blurred iron centre. Using different shaped brushes and applications you will be able to develop different patterning.

The two main chemicals in this solution can easily be adjusted, just be aware that iron is much more intense than the copper nitrate.

Leave parts of the dark base coat or bronze visible for contrast.

Finishing Touches

1. Sealing

Sculpt Nouveau Smart Coat (1K Polymer Sealant) / Incralac Lacquer

Apply thin coats at room temperature using a soft cloth or brush.

Allow each coat to dry completely before applying the next.

2. Highlighting

Mix a small amount of pigment with the sealant and use a sponge or brush to add subtle highlights where needed.

3. Shadowing

Prepare a translucent paste by thinning graphite wax with clear wax.

Apply to create shadows or darken areas as desired, either under or over the final wax layers.

Final Waxing

Renaissance Wax / Paste wax /Ceramic Wax

Apply thin layers with a soft brush.

Let each layer sit for 10 minutes to evaporate, then buff to a hard finish.

Repeat 3–4 times for a rich, durable surface.

Tips for Success

Avoid overloading the brush to prevent solid, opaque patches. Focus on a light, broken texture and gradually build up a consistent pattern.

Control heat to avoid unwanted discolouration.

Sealing enhances the patina’s vibrancy, much like dipping a dusty pebble in water to reveal its colours.

Adjust the recipe to develop variations to suit your specific needs.